One of the largest Manufacturers & Suppliers of Slip On Flanges, SORF Flanges, Carbon Steel Slip On Flanges, SS Slip On Flanges, Alloy Steel Slip On Flanges, Nickel Slip On Flange, Inconel Slip On Flanges, Monel Slip On Flanges, ASTM A182 Slip On Flanges, Hastelloy Slip On Flanges Suppliers in india, Bahrain

We are Leading Manufacturers of Slip On Flanges SORF Flanges & have huge stock of 304 Slip On Flanges, 316 Slip On Flanges, astm a105 Slip On Flanges, astm a182 Slip On Flanges as per asme / ansi B16.5 slip on flanges, ansi B16.47 slip on flanges, Din slip on flanges, jis slip on flanges Slip On Flanges Manufacturers & uni slip on flanges Standards.

Best Price Slip On Flanges, SORF Flanges in all size, classes & dimensions like Class 150lbs Slip On Flanges, Class 300 Slip On Flanges, Class 900 Slip On Flanges, Class 1500 Slip On Flanges, Class 2500 Slip On Flanges & pn10 SO flanges in india, Nigeria

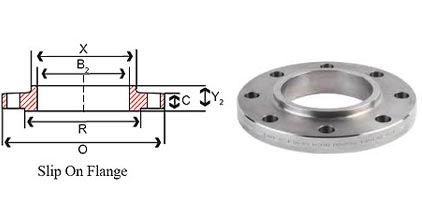

We are Manufacturer, Supplier and Exporter of Slip-on pipe flange, ASME 16.5 Slip On Flanges / SORF Flanges. Slip-on pipe flange usually slips over the pipe. Slip-on pipe flanges are typically made with an inside diameter of the pipe flange slightly larger than the outside diameter of the pipe. This allows the slip-on flange to slip over the pipe. Slip-on pipe flanges are welded (usually both inside and outside) to provide strength and prevent leakage. Slip-on pipe flanges can sometimes also have a boss/ring or hub, and can be made with a bore to suit either pipe or tube. Ring pipe flanges and hub pipe flanges are both considered slip-on pipe flanges because they both slip over the pipe. Slip-on flanges are easy to use in fabricated applications. These flanges are attached to the pipe by fillet welding at the hub and at the end of the pipe inside the flange. These are available in wide variety of sizes and applications.

Randhir Metal is a Higly Acclaimed manufacturer & supplier of Slip On Flanges, Slip On Flanges, Blind Slip On Flange, Weld Neck Flanges & Slip On Flanges Pipe Fittings. A Slip On Flanges is a disc, collar or ring that attaches to pipe with the purpose of providing increased support for strength, blocking off a pipeline or implementing the attachment of more items. They are usually welded or screwed to the pipe end and are connected with bolts. A gasket is also fixed between the two mating flanges to provide a tighter seal.

We carry an endless variety of Slip On Flanges products that have an infinite amount of uses, Check with us for the right Blind flanges choice for your job.

Manufacturers Of Slip on Flange in India :

Slip on Flanges are slipped over the pipe and welded inside and outside, according to ANSI B16.5/ANSI B16.47 Series A/ANSI B16.47 Series B American Standard. We also manufacture DIN Standard, BS Standard, JIS Standard, GOST Standard,as per customers requirements & drawings. Slip on Flange Manufacturer in India Class 150 to Class 2500 Slip on Flanges, Type of sealing face RF, FF & RTJ, material in kinds of Carbon Steel, Low Temperature Carbon Steel, Alloy Steel, Stainless Steel,Inconel & Hastelloy.

|

|---|

Manufacturing of Slip on Flange |

We Manufacturer Slip on Flanges :

- ASTM A182 Slip on Flange, 2 inch, 300#, ANSI b16.5, RF

- ASTM A182 F304 Slip on Flanges, 150 LB, 2 INCH, RF

- ASTM A182 F317L SO Flange, 300#, 4 inch, ANSI b16.5

- Manufacturers of ASME b16.5 SS Slip on Flanges ASTM A182 F304 6 inch 150#

|

|---|

SS 304 Slip On Flanges Manufacturing |

SS 304 Slip On Flanges Manufacturer :

ASME B16.5 SS Slip on Flange Manufacturer in India Offering great Price of ASME B16.5 SS Slip on Flange, ASTM A182 F304, 6 Inch, 150#, PicklingTreatment.

|

|---|

Manufacturing of SS 317L Slip On Flange |

SS 317L Slip On Flange Manufacturers :

ASTM A182 F317L Slip on Flange Manufacturer in India quoting exciting price offer on ASTM A182 F317L Slip on Flanges, 4 Inch, 300lbs, ANSI B16.5, Raised Face Flanges

|

|---|

Manufacturing of 316L Stainless Steel Slip On Flange |

316L Stainless Steel Slip On Flange Manufacturers

ASTM A182 Slip on Flange Manufacturer quoting special price on surplus & ready stock of ASTM A182 F316L Slip-on Flange, 2 Inch (DN 50), CL300, ANSI B16.5, Raised Face, SO flange.

|

|---|

Ready Stock of SS 304 Slip on Flange |

SS 304 Slip On Flange Manufacturers in India

ASTM A182 F304 Slip-on Flange Manufacturer in India offering best price on ASTM A182 F304 Slip-on Flanges, 2 Inch (DN 50), 150 LB, ANSI B16.5, RF face.

ASME/ ANSI B16.5 Slip On (SO) Pipe Flanges Manufacturing Materials :

| Dimensions | Base Material | Pressure Rating |

|---|---|---|

| ASME B16.5 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| API 605 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| ASME B16.47series A & B | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| EN1092-1 | ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. PN250. PN320. PN400. |

| BS4504 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. |

| BS10 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | Table D. Table E. Table F. Table H. Table J. Table K. Table R. Table S.Table T. |

Slip On Flanges / SORF Flanges

- Slip On Flanges Price

- Leading manufacturer of Slip On Flanges

- Our Live Stock of Slip On Flanges

- Slip On Flanges Application

Slip-on flanges are available with raised, flat or RTJ faces, and are also available in orifice configurations.

|

Dimensions of Slip On ASME B16.5

Dimensions of Slip On ASME B16.5 – class 150 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Slip On | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 90 | 9.6 | 35.05 | 30 | 22.2 | 14 | 4 | 15.87 | 60.3 |

| 3/4″ | 100 | 11.2 | 42.93 | 38 | 27.7 | 14 | 4 | 15.87 | 69.9 |

| 1″ | 110 | 12.7 | 50.80 | 49 | 34.5 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4″ | 115 | 14.3 | 63.50 | 59 | 43.2 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2″ | 125 | 15.9 | 73.15 | 65 | 49.5 | 21 | 4 | 15.87 | 98.4 |

| 2″ | 150 | 17.5 | 91.95 | 78 | 61.9 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2″ | 180 | 20.7 | 104.65 | 90 | 74.6 | 27 | 4 | 19.05 | 139.7 |

| 3″ | 190 | 22.3 | 127.00 | 108 | 90.7 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2″ | 215 | 22.3 | 139.70 | 122 | 103.4 | 30 | 8 | 19.05 | 177.8 |

| 4″ | 230 | 22.3 | 157.22 | 135 | 116.1 | 32 | 8 | 19.05 | 190.5 |

| 5″ | 255 | 22.3 | 185.67 | 164 | 143.8 | 35 | 8 | 22.22 | 215.9 |

| 6″ | 280 | 23.9 | 215.90 | 192 | 170.7 | 38 | 8 | 22.22 | 241.3 |

| 8″ | 345 | 27.0 | 269.75 | 246 | 221.5 | 43 | 8 | 22.22 | 298.5 |

| 10″ | 405 | 28.6 | 323.85 | 305 | 276.2 | 48 | 12 | 25.40 | 362.0 |

| 12″ | 485 | 30.2 | 381.00 | 365 | 327.0 | 54 | 12 | 25.40 | 431.8 |

| 14″ | 535 | 33.4 | 412.75 | 400 | 359.2 | 56 | 12 | 28.57 | 476.3 |

| 16″ | 595 | 35.0 | 469.90 | 457 | 410.5 | 62 | 16 | 28.57 | 539.8 |

| 18″ | 635 | 38.1 | 533.40 | 505 | 461.8 | 67 | 16 | 31.75 | 577.9 |

| 20″ | 700 | 41.3 | 584.20 | 559 | 513.1 | 71 | 20 | 31.75 | 635.0 |

| 24″ | 815 | 46.1 | 692.15 | 663 | 616.0 | 81 | 20 | 34.92 | 74 |

1,6mm raised face not included in the E & H dimensions

Dimensions of Slip On ASME B16.5 – class 300 Lbs

| Nominal Bore Slip On | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 21.3 | 12.7 | 35.05 | 38 | 22.2 | 21 | 4 | 15.87 | 66.7 |

| 3/4″ | 26.7 | 14.3 | 42.93 | 48 | 27.7 | 24 | 4 | 19.05 | 82.6 |

| 1″ | 33.4 | 15.9 | 50.80 | 54 | 34.5 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 42.2 | 17.5 | 63.50 | 64 | 43.2 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 48.3 | 19.1 | 73.15 | 70 | 49.5 | 29 | 4 | 22.22 | 114.3 |

| 2″ | 60.3 | 20.7 | 91.95 | 84 | 61.9 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 73.0 | 23.9 | 104.65 | 100 | 74.6 | 37 | 8 | 22.22 | 149.2 |

| 3″ | 88.9 | 27.0 | 127.00 | 117 | 90.7 | 41 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 101.6 | 28.6 | 139.70 | 133 | 103.4 | 43 | 8 | 22.22 | 184.2 |

| 4″ | 114.3 | 30.2 | 157.22 | 146 | 116.1 | 46 | 8 | 22.22 | 200.0 |

| 5″ | 141.3 | 33.4 | 185.67 | 178 | 143.8 | 49 | 8 | 22.22 | 235.0 |

| 6″ | 168.3 | 35.0 | 215.90 | 206 | 170.7 | 51 | 12 | 22.22 | 269.9 |

| 8″ | 219.1 | 39.7 | 269.75 | 260 | 221.5 | 60 | 12 | 25.40 | 330.2 |

| 10″ | 273.0 | 46.1 | 323.85 | 321 | 276.2 | 65 | 16 | 28.57 | 387.4 |

| 12″ | 323.8 | 49.3 | 381.00 | 375 | 327.0 | 71 | 16 | 31.75 | 450.8 |

| 14″ | 355.6 | 52.4 | 412.75 | 425 | 359.2 | 75 | 20 | 31.75 | 514.4 |

| 16″ | 406.4 | 55.6 | 469.90 | 483 | 410.5 | 81 | 20 | 34.92 | 571.5 |

| 18″ | 457.0 | 58.8 | 533.40 | 533 | 461.8 | 87 | 24 | 34.92 | 628.6 |

| 20″ | 508.0 | 62.0 | 584.2td> | 587 | 513.1 | 94 | 24 | 34.92 | 685.8 |

| 24″ | 610.0 | 68.3 | 692.15 | 702 | 616.0 | 105 | 24 | 41.27 | 812.8 |

1,6mm raised face not included in the E & H dimensions

Dimensions of Slip On ASME B16.5 – class 600 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Slip On | Dia. (D) | Thick. (E) | Dia. (F) | Dia. (B) | Dia. (A) | Height1 (H) | Nbr | Holes | Dia. (C) |

| 1/2″ | 21.3 | 14.3 | 35.05 | 38 | 22.2 | 22 | 4 | 15.87 | 66.7 |

| 3/4″ | 26.7 | 15.9 | 42.93 | 48 | 27.7 | 25 | 4 | 19.05 | 82.6 |

| 1″ | 33.4 | 17.5 | 50.80 | 54 | 34.5 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 42.2 | 20.7 | 63.50 | 64 | 43.2 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 48.3 | 22.3 | 73.15 | 70 | 49.5 | 32 | 4 | 22.22 | 114.3 |

| 2″ | 60.3 | 25.4 | 91.95 | 84 | 61.9 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 73.0 | 28.6 | 104.65 | 100 | 74.6 | 41 | 8 | 22.22 | 149.2 |

| 3″ | 88.9 | 31.8 | 127.00 | 117 | 90.7 | 46 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 101.6 | 35.0 | 139.70 | 133 | 103.4 | 49 | 8 | 25.40 | 184.2 |

| 4″ | 114.3 | 38.1 | 157.22 | 152 | 116.1 | 54 | 8 | 25.40 | 215.9 |

| 5″ | 141.3 | 44.5 | 185.67 | 189 | 143.8 | 60 | 8 | 28.57 | 266.7 |

| 6″ | 168.3 | 47.7 | 215.90 | 222 | 170.7 | 67 | 12 | 28.57 | 292.1 |

| 8″ | 219.1 | 55.6 | 269.75 | 273 | 221.5 | 76 | 12 | 31.75 | 349.2 |

| 10″ | 273.0 | 63.5 | 325.85 | 343 | 276.2 | 86 | 16 | 34.92 | 431.8 |

| 12″ | 323.8 | 66.7 | 381.00 | 400 | 327.0 | 92 | 20 | 34.92 | 489.0 |

| 14″ | 355.6 | 69.9 | 412.75 | 432 | 359.2 | 94 | 20 | 38.10 | 527.0 |

| 16″ | 406.4 | 76.2 | 469.90 | 495 | 410.5 | 106 | 20 | 41.27 | 603.2 |

| 18″ | 457.0 | 82.6 | 533.40 | 546 | 461.8 | 117 | 20 | 44.45 | 654.0 |

| 20″ | 508.0 | 88.9 | 584.20 | 610 | 513.1 | 127 | 24 | 44.45 | 723.9 |

| 24″ | 610.0 | 101.6 | 692.15 | 718 | 616.0 | 140 | 24 | 50.80 | 838.2 |

Our Live Stock of Slip On Flanges

|  |  |

|  |  |

DIN Cartbon Steel 6bar Slip-on Flanges, Blind Flanges, Welding Neck Flanges FOB Price: $1.3 - $1.5 / Piece | ||

|  |  |

Leading manufacturer of Slip On Flanges

We also having stock of Slip On Flanges & other Stainless Steel Flanges, Carbon Steel Flanges, Alloy Steel Flanges manufactured by :

| Erne Fittings, Austria | Metal far, Italy | Lame S.R.l., Italy |

| BENKAN Corporation, Japan | BKL- Thai Benkan, Thailand | TecnoForge, Italy |

| Ulma, Spain | Mega, Italy | Melesi, Italy |

| Interfit, France | Raccortubi S.P.A., Italy |

Specifications, Dimensions Slip-on Flanges

- ANSI/ASME B16.5 Slip-on Flange 150lb

- ANSI/ASME B16.5 Slip-on Flange 300lb

- ANSI-ASME B16.5 Slip-on Flange 400lb

- ANSI/ASME B16.5 Slip-on Flange 600lb

- ANSI/ASME B16.5 Slip-on Flange 900lb

- ANSI/ASME B16.5 Slip-on Flange 1500lb

|

|

- ansi standard class150 forged steel slip on flange

US $0.66-1.36 / Piece - rasied face slip on flanges

US $1-3500 / Piece - DIN 2573 25bar Carbon Steel Forged Slip on Flange With High Quality

US $0.1-20 / Piece - ANSI/ASME B16.5 A182 F304 F304L F51 alloy A182 F1 slip on RF flange

US $0.1-1 / Piece - standard carbon steel slip on flange

US $1.03-1.03 / Piece - CUPRO NICKEL ANSI B16.5 SLIP ON FLANGE

US $10 / Piece - A105 ANSI B16.5 150 LBS slip on RF flange

US $0.1-1 / Piece - Stainless Steel Slip On Flange Ansi B16.5

US $1000-3000 / Piece - EN 1092-1 Carbon Steel LF Stainless Steel Flange Slip On Raised Face

US $0.1-10 / Piece - Customized metal slip on flange

US $1-100 / Piece - DIN 2576 Slip On flange carbon steel stainless steel FF RF flange

US $0.8-1000 / Piece - Best price customize stainless steel slip on flange

US $15-900 / Piece - astm a105 galvanized carbon steel slip on flange

US $0.36-0.63 / Piece - ANSI B16.5 150LBS/300LBS Slip on flange carbon steel

US $800-1700 / Piece - ANSI 150 stainless steel slip on flange

US $5-20000 / Piece - Stainless Steel Slip On Flange Pipe Fittings (1/2-72"sch10-sch160)

US $1.0-1.0 / Piece - Forgedmss sp 44 slip on flanges Carbon Steel Flanges MSS SP44

US $1-10000 / Piece - ASME b16.5 stainless steel slip on blank flange

US $3.8-4.3 / Piece - pipe fitting stainless steel slip on flange

US $0.5-5000 / Piece - Custom stainless steel slip on flange

US $6.0-14.0 / Piece - Widely Use stainless steel Slip On Flange

US $700-950 / Piece - A105 ANSI B16.5 150 LBS slip on RF flange

US $1.6-50 / Piece - ASME Carbon steel Slip On flange

US $10-1000 / Piece - Din standard carbon steel slip on flange

US $0.2-2000 / Piece - AWWA C207 Slip On flange

US $1-5 / Piece - Slip on flange

US $1-1000 / Piece - ASTM a105 galvanized Carbon steel Slip on flangee

US $2-50 / Piece - AWWA C207 Carbon Steel Slip On Flange

US $1-10000 / Piece - ANSI150 Stainless steel slip on flange PN10/PN16

US $2-100 / Piece - slip on flange/jis flange/slip blind flange

US $0.2-200 / Piece - stainless steel slip on flange pn16 exporters india

US $0.1-10 / Piece - A182 F316 FRP slip on stainless steel weld neck forged flange

US $2-13 / Piece - Titanium wide slip on jis rtj ansi flange

US $1-99 / Piece - bs4504 dn1000 pn16 aluminum slip on flange

US $1000-2000 / Piece

Manufacturers of Different Types Of Flanges, listed below

Locate our dealers & distributors in following Countries, Cities

| Indonesia | Malaysia | Singapore |

| Vietnam | Philippines | United Arab Emirates |

| Saudi Arabia | Iraq | Iran |

| Turkey | Egypt | Oman |

| Kuwait | Qatar | Bahrain |

| Nigeria | Kenya | Tanzania |

| South Africa | United States of America | Canada |

| Italy | Netherlands | Germany |

| Mexico | Australia | New Zealand |

What & Where we supply